41-Minute Rapid Sintering Zirconia: Revolutionizing Dental Restorations with Speed, Strength, and Aesthetics

2025-12-31

2025-12-28

The evolution of CAD/CAM technology has made zirconia and glass ceramics—particularly lithium disilicate—the leading all-ceramic materials for dental restorations. These options offer metal-free alternatives with excellent biocompatibility and precision fit. The global dental CAD/CAM market is valued at approximately $3.1 billion in 2025, projected to reach $7.48 billion by 2034 at a CAGR of 10.29%, driven by rising demand for aesthetic and durable solutions amid oral diseases affecting over 3.5 billion people worldwide.

Zirconia provides unmatched strength for high-load areas, while lithium disilicate excels in translucency for natural-looking results. North America holds about 36% market share due to high adoption in clinics, Europe prioritizes aesthetics, and Asia-Pacific grows fastest with increasing access to digital tools.

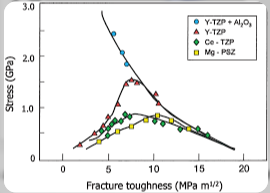

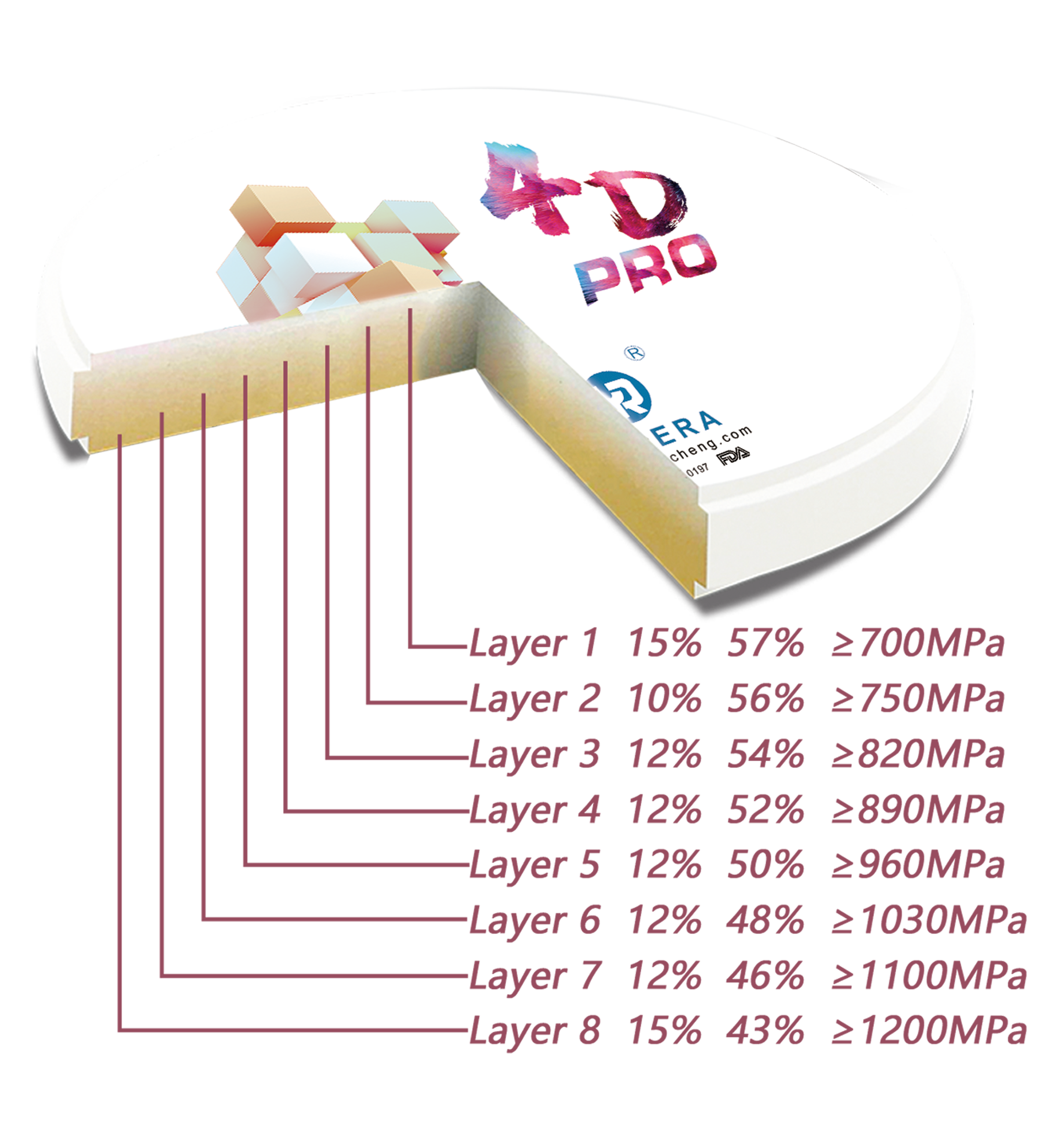

Zirconia boasts flexural strength of 900-1200 MPa, far superior to lithium disilicate's 360-550 MPa. This makes zirconia ideal for posterior crowns, bridges, and implant-supported restorations under heavy occlusal forces.

Monolithic zirconia minimizes chipping risks common in layered systems. Lithium disilicate, while strong enough for single units, requires thicker designs (1-1.5 mm minimum) and is prone to fracture in long-span or high-stress cases.

Lithium disilicate offers superior translucency and fluorescence, closely mimicking natural enamel for anterior veneers, crowns, and inlays. High-translucency zirconia variants have improved aesthetics, but traditional forms appear more opaque.

For high smile-line cases, lithium disilicate remains the gold standard. Multi-layer zirconia bridges the gap for balanced strength and beauty in visible areas.

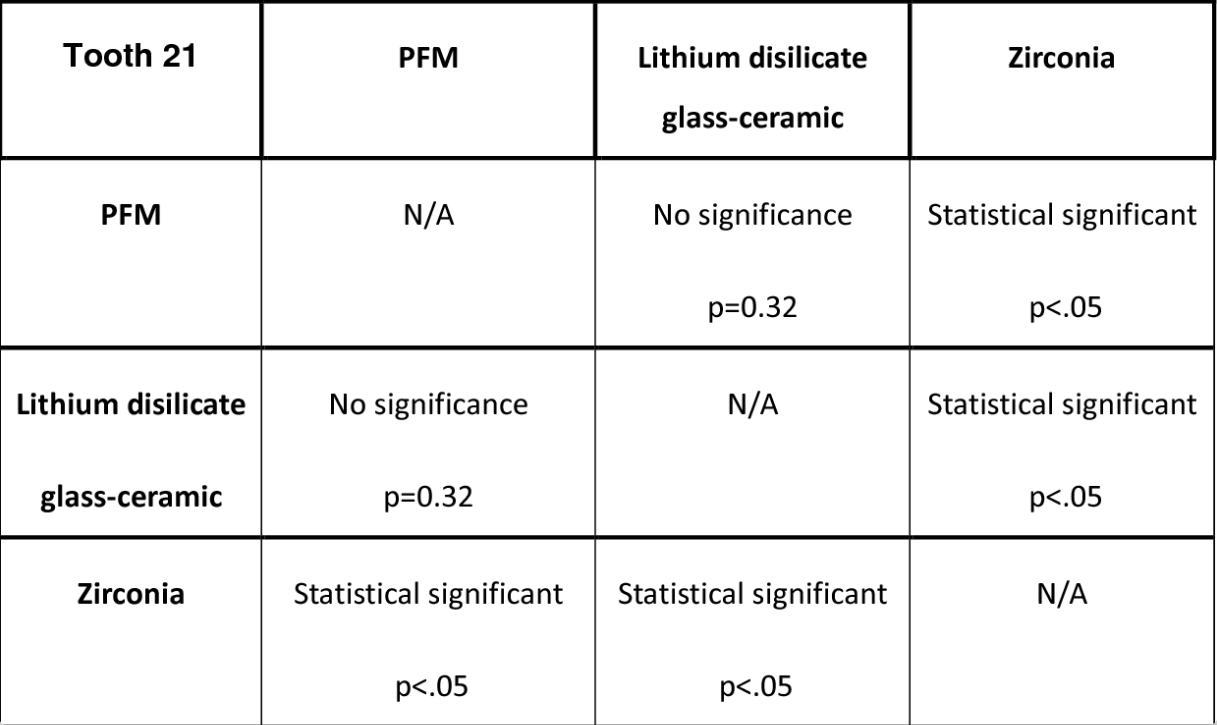

Both materials show excellent 5-year survival rates exceeding 95% for single crowns. Zirconia performs better in posterior and implant cases due to lower fracture risk, while lithium disilicate shines in anterior with minimal complications.

Systematic reviews indicate similar biological outcomes (periodontal, endodontic) compared to metal-ceramics. Failures in zirconia often involve veneer chipping (in layered types), while lithium disilicate risks bulk fracture under load.

Lithium disilicate suits chairside wet milling for same-day restorations, with quick crystallization. Zirconia typically requires dry milling and longer sintering, better for lab production but increasingly chairside-compatible with fast furnaces.

Both integrate well with digital workflows, offering precise margins (<50 microns fit).

Zirconia can cause more opposing tooth wear due to hardness, though polished surfaces mitigate this. Lithium disilicate is kinder to antagonists, similar to enamel.

Both exhibit low plaque accumulation and high biocompatibility, reducing gingival irritation.

Zirconia often costs more due to material and processing, but longevity offsets expenses in high-risk cases. Lithium disilicate is competitive for aesthetics-focused treatments.

Regional factors: North America favors zirconia for strength in diverse populations; Europe leans toward lithium disilicate for premium cosmetics; Asia-Pacific adopts both rapidly with growing clinics.

| Flexural Strength | 900-1200 MPa | 360-550 MPa |

| Translucency | Moderate (improved in high-trans types) | High |

| Ideal Location | Posterior, bridges, implants | Anterior, veneers, inlays |

| Minimum Thickness | 0.5-1 mm | 1-1.5 mm |

| 5-Year Survival | >95% (excellent in load-bearing) | >95% (excellent in aesthetics) |

| Opposing Wear | Higher (if unpolished) | Low |

| Chairside Suitability | Good (with fast sintering) | Excellent (wet milling) |

Consult patient-specific risks; both achieve >95% success when indicated properly.

Conclusion

Zirconia and lithium disilicate represent pinnacle CAD/CAM materials, each excelling in different scenarios. Zirconia dominates strength and longevity for demanding cases, while lithium disilicate leads in aesthetics for smile enhancements. As the market expands in 2025, informed selection ensures optimal outcomes, patient satisfaction, and practice efficiency worldwide.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more

2025-12-31

2025-11-30

2025-12-30