Clinical Application of Three-Dimensional Data Acquisition Technology in Dentistry

2024-10-24

2025-12-23

The production of dental zirconia blocks follows a rigorous, multi-step process to ensure high quality, strength, and aesthetics for CAD/CAM applications. Below is a detailed English translation and description of the process.

The first step is powder mixing in a dedicated workshop equipped with three-dimensional mixers and V-type mixers. Parameters for formulation and mixing time are set according to the characteristics of different powders. Professional personnel strictly follow the recipe proportions to blend the raw material—zirconia powder—and then distribute it to the dry pressing workshop for shaping.

The second step is dry pressing, divided into two types: a white zirconia forming workshop and a colored zirconia forming workshop. The mixed powder is pressed into initial block shapes.

Next, the vacuum-packaged zirconia blocks are transferred to the cold isostatic pressing workshop. These blocks are very fragile after vacuum packaging and require immediate CIP. The hydraulic machine uses water as a medium to apply uniform pressure, resulting in reduced volume and significantly increased density.

After processing, the blocks undergo dimensional and quality inspections. Qualified blocks then proceed to pre-sintering.

In the pre-sintering workshop,the sintering line is divided into low-temperature, medium-temperature, and high-temperature zones. The low- and medium-temperature zones primarily debind the blocks—since the zirconia powder contains binders, gradual heating evaporates the organic material. Finally, the high-temperature zone further increases product density. Qualified blocks are cooled and allowed to rest by category before being sent to the shape machining workshop.

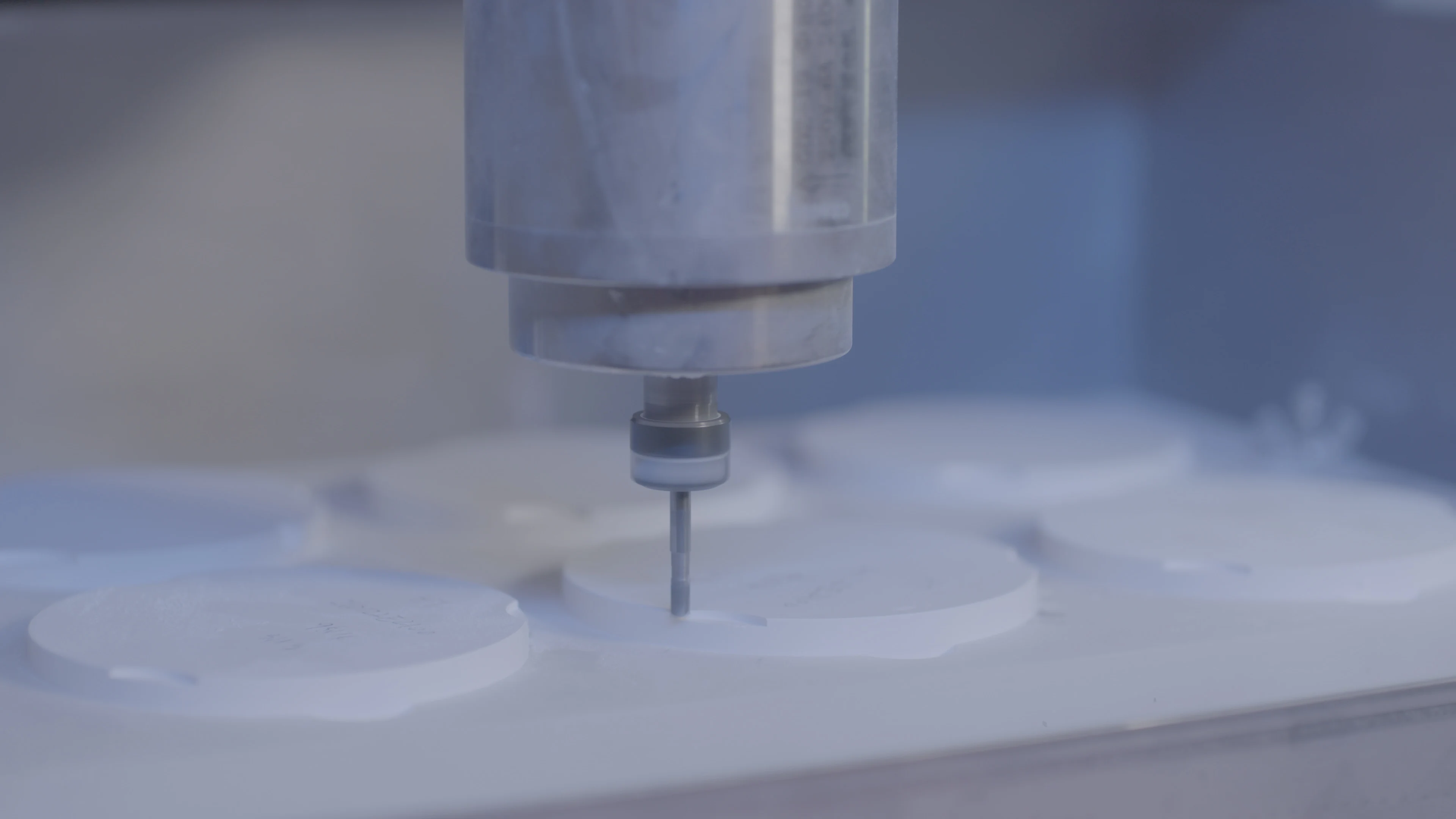

In the shape machining workshop, blocks are processed on machine tools according to customer-specified dimensions and appearances, ensuring standardized and precise external forms.

Qualified blocks after shape machining are sent to the printing and packaging room. The printing technology used is laser printing, capable of processing 100 blocks per hour. Equipped with UV lamps, it dries the ink directly during printing to prevent smudging.

Finally, fully qualified zirconia blocks are packaged and shipped.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more