Advantages of Digital Complete Denture

2024-12-31

2026-01-10

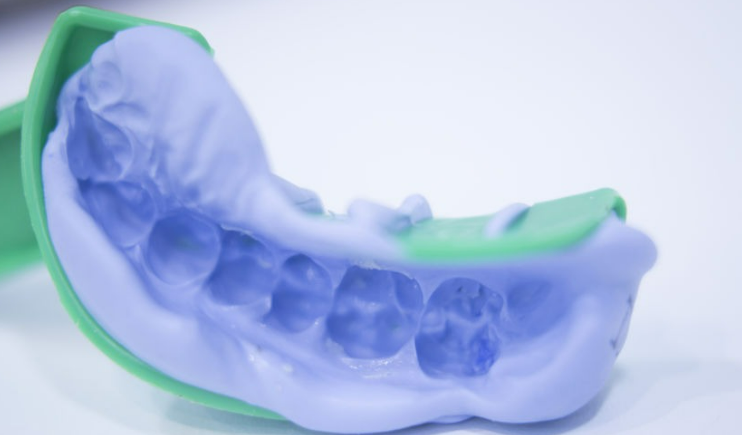

In the rapidly evolving field of dentistry, traditional dental impressions—once the gold standard for creating molds of patients' teeth and gums—are increasingly viewed as outdated. These conventional methods, which involve filling trays with gooey materials like alginate or silicone and having patients bite down until they set, have served the industry well for decades. However, as we enter 2026, digital scanning technology is revolutionizing the process, offering undeniable advantages in comfort, accuracy, efficiency, and cost-effectiveness. This shift is not just a trend but a necessity driven by patient demands and technological advancements, particularly in tech-savvy regions like Santa Clara, California, where innovation in healthcare is at the forefront.

One of the primary reasons traditional impressions are fading is their impact on patient comfort. Traditional methods often trigger gag reflexes in about 25% of patients due to the bulky trays and unpleasant, viscous materials that can cause nausea or discomfort during the 10-15 minute process per arch. In contrast, digital intraoral scanners use a small, wand-like device to capture 3D images in just 2-5 minutes, reducing gag incidents to under 5%. Patients report a cleaner, less invasive experience, with 89% preferring digital over analog methods. This improvement is crucial in areas like Santa Clara, where busy professionals seek quick, comfortable dental care without disrupting their schedules.

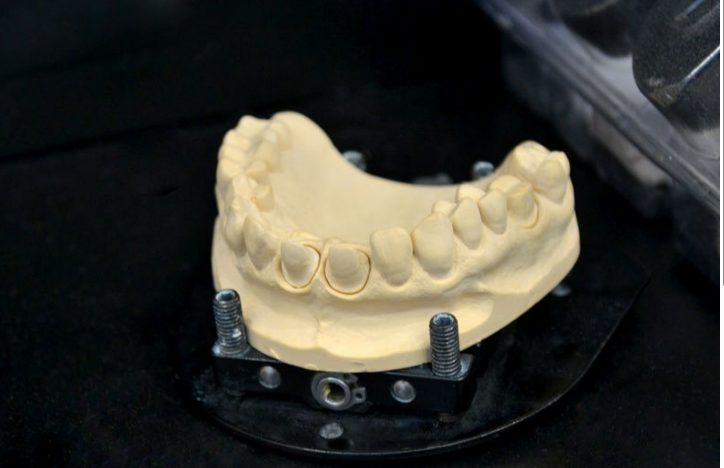

Accuracy is another area where traditional impressions fall short. These physical molds are prone to distortions from material shrinkage (up to 1%), bubbles, or improper handling during transport and pouring into plaster models. Such errors lead to remake rates as high as 7%, necessitating additional appointments. Digital impressions, however, produce high-resolution 3D models with superior trueness and precision, especially for crowns, bridges, and aligners, dropping remake rates to under 3%. While some studies show conflicting data on full-arch accuracy, digital methods generally outperform in most clinical scenarios, allowing real-time adjustments and eliminating human error in model creation.

Time efficiency further highlights the obsolescence of traditional techniques. Conventional impressions require multiple steps: mixing materials, setting time, disinfection, shipping to labs, and model fabrication, often taking days. This delays treatments and increases lab processing by 1-2 days per case. Digital scanning streamlines the workflow; images are captured instantly and transmitted electronically, enabling same-day restorations in many cases and reducing overall treatment time by 30-50%. For dentists in high-demand areas like Santa Clara, this means higher patient throughput and better practice efficiency.

From a cost perspective, traditional impressions may seem cheaper initially, but they accrue higher long-term expenses. Consumables like trays, materials, and plaster add up, plus costs from remakes and storage. Digital systems, despite upfront investments, lower material waste, cut lab fees by 20-40%, and minimize errors, leading to better ROI over time. Market data supports this: by 2027, 65% of dental practices are projected to adopt digital impressions, driven by compatibility with CAD/CAM workflows and patient expectations for modern care.

Industry trends in 2026 underscore this transition. Digital dentistry, including AI-integrated scanning and cloud-based collaboration, is growing rapidly, with the global market emphasizing seamless integration for prosthetics, orthodontics, and implants. Traditional molds cannot easily interface with these digital ecosystems, requiring extra digitization steps that introduce inaccuracies. In regions like California, where digital health innovations thrive, practices sticking to analog methods risk losing competitive edge as patients gravitate toward tech-forward providers.

In conclusion, traditional dental impressions are outdated due to their discomfort, lower accuracy, inefficiency, higher costs, and incompatibility with modern digital tools. As dentistry advances in 2026, embracing digital scanning not only enhances patient satisfaction but also optimizes clinical outcomes. For residents in Santa Clara and similar tech hubs, this means accessing cutting-edge care that prioritizes comfort and precision. If you're considering dental work, ask your provider about digital options—it's the future of smiles.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more