Is CAD CAM the Same as CEREC?

2025-10-10

2026-01-23

The dental industry in Eastern Europe is experiencing rapid digital transformation, with sintering furnaces at the core of zirconia-based restorations. These high-temperature devices enable efficient production of crowns, bridges, and implants in labs and clinics. As adoption of chairside and fast sintering rises, the supply chain for these furnaces faces unique challenges and opportunities in countries like Poland, Hungary, Romania, and the Czech Republic. EU membership provides regulatory alignment but also exposes the region to global disruptions, while economic growth and dental tourism drive demand.

Eastern Europe's dental market benefits from increasing investments in modern infrastructure and rising patient expectations for same-day restorations. The broader European dental sector is projected to grow significantly, with digital tools like CAD/CAM and sintering furnaces playing a key role. Regional adoption is accelerated by lower operational costs compared to Western Europe and a burgeoning medical tourism sector attracting patients from higher-cost countries.

Sintering furnaces rely on specialized components: high-purity heating elements (such as silicon molybdenum rods), advanced insulation materials, precise temperature controllers, and zirconia-compatible chambers. Raw materials like refractories and electronics often originate from global suppliers, with assembly frequently in Asia or Western Europe. In Eastern Europe, furnaces reach clinics via importers, distributors, and local dealers complying with EU Medical Device Regulation (MDR) 2017/745.

The supply chain includes upstream raw material sourcing, manufacturing, import into the EU, distribution to dental labs/clinics, and after-sales support. Eastern European practices increasingly integrate these into CAD/CAM workflows for in-house production, reducing lab dependency.

Global events have highlighted vulnerabilities in dental equipment supply chains. The COVID-19 pandemic caused widespread disruptions, halting production and leading to shortages of consumables and equipment. In Europe, lockdowns reduced elective procedures, impacting demand temporarily but exposing logistical weaknesses.

Geopolitical tensions exacerbate issues. Ongoing conflicts and trade restrictions delay shipments and increase costs for critical components like titanium alloys or electronics. Reports indicate shortages delayed production by up to six months in some cases. Eastern Europe, reliant on imports from Asia and Western Europe, faces amplified risks from port delays, customs bottlenecks, and fluctuating raw material prices.

EU MDR compliance adds complexity. Sintering furnaces classify as Class IIa or IIb medical devices, requiring CE marking, technical documentation, and risk management per ISO 14971. Importers must verify declarations of conformity, UDI labeling, and EUDAMED registration. Non-EU manufacturers appoint authorized representatives, while importers handle traceability and incident reporting. These requirements raise barriers for smaller distributors and increase lead times.

High initial costs and maintenance needs challenge smaller labs in rural Romania or Poland. Skilled technician shortages and energy price volatility affect operations. Supply chain reports note that raw material volatility and logistical issues impact timelines and pricing stability.

Despite challenges, opportunities abound. The region's dental market grows through digital adoption, with CAD/CAM systems expanding rapidly. Eastern Europe benefits from lower costs, skilled labor, and EU funding for healthcare modernization.

Demand for zirconia restorations surges due to their strength and aesthetics, driving furnace needs. Fast sintering technology enables same-day dentistry, appealing to busy clinics and tourists in Budapest or Warsaw. Projections show steady regional growth, aligned with Europe's overall dental equipment expansion.

Localization offers advantages. Establishing regional distribution hubs or partnerships reduces import dependencies and customs delays. EU regulations, while stringent, ensure quality and facilitate cross-border trade within the bloc.

Sustainability trends create niches for energy-efficient furnaces with lower emissions and advanced filtration. These align with EU Green Deal goals, appealing to eco-conscious practices.

Technological integration, including IoT for predictive maintenance, enhances reliability and reduces downtime. Training programs from dental associations build local expertise, supporting adoption in emerging markets.

Dental tourism bolsters demand, with clinics offering competitive pricing for quick restorations. Investments in infrastructure position Eastern Europe as a growth hub.

Clinics and distributors mitigate risks through diversification: sourcing from multiple suppliers and maintaining buffer stock. Partnerships with compliant importers ensure MDR adherence and faster delivery.

Digital tools optimize inventory and forecasting. Investing in local service networks cuts downtime and builds resilience.

Collaboration with EU-funded initiatives supports technology access and training. Monitoring geopolitical developments aids proactive planning.

Eastern Europe's sintering furnace supply chain will evolve with stabilizing global conditions and advancing technology. By 2030, increased digital workflow integration is expected, with furnaces central to efficient restorations.

Opportunities in sustainability, localization, and tourism will drive growth, offsetting challenges. Clinics embracing resilient strategies will thrive, delivering high-quality care amid market expansion.

The supply chain for sintering furnaces in Eastern Europe balances challenges from global disruptions, regulations, and costs with opportunities from digital growth, tourism, and EU alignment. Strategic adaptation positions the region for sustained progress in modern dentistry, benefiting clinics, professionals, and patients across Poland, Hungary, Romania, the Czech Republic, and beyond.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

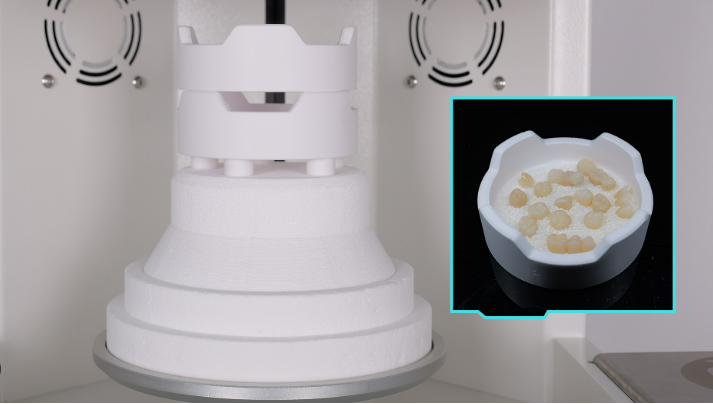

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more