Zirconia Dental Bridges: Comprehensive Guide on Benefits, Costs, and Comparisons

2024-07-20

2026-01-21

The dental industry in Eastern Europe is undergoing a significant digital transformation, driven by the integration of advanced technologies into everyday workflows. Among these innovations, remote monitoring sintering furnaces stand out as a key enabler of efficient, high-quality zirconia restorations. These furnaces, equipped with cloud connectivity and IoT capabilities, allow dental professionals to track sintering processes in real time from anywhere, optimizing operations and reducing downtime. In regions like Poland, Hungary, Romania, and the Czech Republic, where dental tourism and private clinics thrive, cloud-based remote monitoring is accelerating adoption and positioning Eastern European practices at the forefront of modern dentistry.

Eastern Europe's dental market benefits from EU integration, affordable care, and growing investments in digital tools. The European dental equipment sector continues to expand, with projections indicating steady growth through 2032. In Eastern Europe, digital dentistry adoption has surged, fueled by cost-effective solutions and high demand for same-day restorations. Market analyses show that IoT integration in dental devices, including sintering furnaces, supports remote monitoring and data analytics, contributing to overall efficiency. This trend aligns with broader digital health initiatives across the EU, where Eastern European countries leverage subsidies for technology upgrades.

Remote monitoring sintering furnaces connect via WiFi or cellular networks to cloud platforms, transmitting data on temperature curves, cycle progress, voltage, current, and error alerts. Technicians access dashboards on mobile devices or computers to view live status, receive notifications for deviations, and even adjust parameters remotely in some systems. This connectivity ensures precise control over high-temperature processes, typically reaching 1500-1600°C for zirconia densification.

Cloud technology enhances traditional sintering by adding layers of intelligence. Real-time data logging captures every cycle detail, supporting quality assurance and compliance with EU Medical Device Regulation (MDR) requirements. Predictive alerts flag potential issues like heating element wear or temperature inconsistencies before they affect restorations. In dental contexts, this means fewer defects, such as warping or incomplete sintering, leading to stronger zirconia with strengths over 1000 MPa and improved translucency.

In Eastern Europe, where clinics often manage high volumes from local and international patients, remote monitoring reduces the need for constant on-site supervision. A furnace running overnight can be checked remotely, freeing staff for patient care or other tasks.

Cloud-enabled remote monitoring delivers multiple advantages tailored to the region's dental landscape.

Data from industry reports highlight IoT adoption driving 15-20% efficiency gains in connected equipment. In Eastern Europe, where digital dentistry grows at 8-10% annually, cloud monitoring accelerates this shift.

Eastern European countries lead in cost-sensitive digital adoption. Poland's labs in Krakow and Gdansk integrate cloud features to handle tourism-driven demand. Hungary's Budapest clinics use remote monitoring for high-throughput operations, supporting 500,000+ annual international patients. Romania and the Czech Republic benefit from EU funds covering 20-30% of upgrades, promoting compliant technologies.

Market projections show the dental sintering furnace sector expanding globally at a CAGR of around 6-7% through 2032, with IoT and cloud integration as major drivers. In Europe, over 5,000 units now feature connectivity, enabling firmware updates and predictive alerts. Eastern Europe's focus on zirconia—preferred for biocompatibility and aesthetics—pairs well with these advancements, as remote monitoring ensures optimal cycles for high-translucency materials.

Challenges include initial connectivity setup and cybersecurity concerns, but robust encryption and role-based access mitigate risks. Training programs from dental associations help staff adapt quickly.

The workflow integrates seamlessly with CAD/CAM systems:

Advanced features include AI-driven adjustments for adaptive heating and segmented cooling to prevent thermal stress. Energy consumption drops with optimized cycles, supporting sustainability goals.

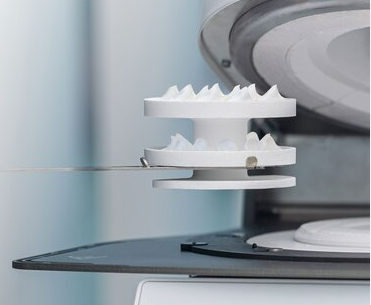

In Eastern Europe, this enables clinics to process more units per day, with some systems handling double-layer stacking for higher capacity.

Cloud technology will evolve with AI for automated diagnostics and predictive maintenance, potentially achieving 90% failure prediction accuracy. Integration with broader dental ecosystems—scanners, mills, and patient management software—creates fully connected workflows.

By 2030, Eastern Europe could see 50-60% of clinics adopting connected devices, driven by tourism growth and regulatory alignment. Emerging hybrid models combine sintering with glazing, further reducing times.

Sustainability remains key; energy-efficient, cloud-monitored furnaces align with EU Green Deal targets.

Remote monitoring sintering furnaces powered by cloud technology represent a pivotal advancement for Eastern European dentistry. By enabling real-time control, predictive insights, and seamless integration, they boost efficiency, quality, and competitiveness. In Poland, Hungary, Romania, and beyond, this rise supports patient-focused care and economic growth in a thriving sector. As adoption accelerates, cloud-connected furnaces will define the next era of precise, accessible zirconia restorations.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

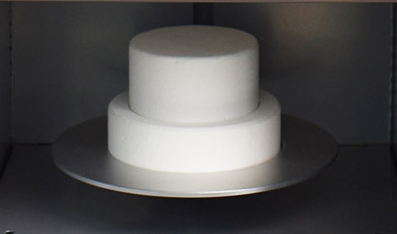

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more