Fast Sintering Furnaces for Monolithic Zirconia in 2025: Cycle Times, Energy Use, and Specs

2025-11-21

2026-01-27

Desktop dental scanners, essential for digitizing gypsum models, impressions, dies, and articulators in CAD/CAM workflows, represent a significant investment for dental laboratories. Proper maintenance ensures high accuracy, minimizes downtime, and extends equipment lifespan, often beyond 7-10 years with consistent care. In Eastern Europe, where labs in Poland, Hungary, Romania, and the Czech Republic support growing digital adoption and dental tourism, effective maintenance optimizes costs and competitiveness. Adhering to best practices protects precision optics, reduces repair needs, and maintains compliance with EU standards like ISO 13485 for quality management in medical device production.

The dental lab equipment market in Europe grows steadily, with Eastern regions benefiting from EU funding and increasing demand for precise restorations. Regular maintenance can reduce unexpected failures by up to 50%, as seen in general lab equipment studies, while preserving scan accuracy critical for zirconia crowns, bridges, and implants.

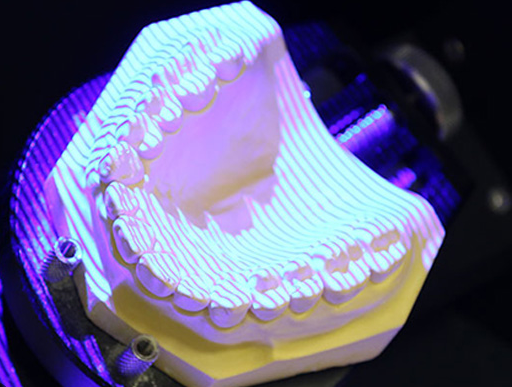

Desktop scanners use optical or laser technology to capture 3D data from physical models with micron-level precision. Key components include cameras, light sources, mirrors, motors, and calibration targets. Environmental factors like dust, humidity, and temperature fluctuations—common in Eastern European labs—can degrade performance if unaddressed. Preventive care focuses on protecting optics, ensuring mechanical stability, and maintaining software integrity.

Cleaning prevents dust and debris from affecting scan quality. Daily routines include:

Weekly deep cleaning involves inspecting and cleaning calibration tools and accessories. Proper cleaning maintains image clarity and prevents calibration errors.

Calibration ensures ongoing accuracy. Most desktop scanners require periodic calibration, typically every 7-30 days or after environmental changes, heavy use, or transport.

Regular performance tests, such as scanning known reference models, detect deviations early. Inconsistent accuracy often signals the need for recalibration or service.

Eastern Europe's variable climate affects equipment. Maintain optimal lab conditions:

These controls extend component life by reducing wear on motors and electronics.

Keep software current for bug fixes, improved algorithms, and security. Check for updates monthly and install promptly. Backup configuration files before updates to avoid workflow disruptions.

Inspect moving parts quarterly:

Replace consumables like calibration targets when worn.

Implement a structured schedule:

Documentation tracks maintenance and supports compliance audits.

Address problems promptly:

Early intervention prevents major failures.

Proper maintenance yields:

Labs in Warsaw, Budapest, and Bucharest report extended lifespans through routine care.

Advancements include self-diagnostic tools and AI monitoring. Labs adopting these will further enhance longevity.

Maintenance best practices for desktop dental scanners—cleaning, calibration, environmental control, updates, and inspections—extend lifespan, ensure accuracy, and support efficient operations in Eastern European labs. By prioritizing preventive care, labs in Poland, Hungary, Romania, and the Czech Republic maximize their investment in digital dentistry, delivering high-quality restorations reliably.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more