Introduction: Material Versatility in Modern Digital Dentistry

Dental CAD/CAM milling machines have transformed restorative workflows by enabling precise, in-house fabrication of crowns, bridges, veneers, inlays, onlays, abutments, and frameworks. A key question for labs and clinics—especially in high-demand areas like Los Angeles with diverse cosmetic and implant cases—is how many materials one machine can reliably process.

Modern mills handle 5–10+ common dental materials, including pre-sintered zirconia, PMMA, wax, PEEK, composites, glass ceramics (including lithium disilicate), hybrid ceramics, titanium, and pre-sintered CoCr. Versatility depends on hardware: spindle speed/power, cooling system (wet/dry/hybrid), axes (4 vs 5), tool changer capacity, and rigidity. The global dental CAD/CAM market, growing at ~10% CAGR to reach billions by 2030s, reflects rising demand for multi-material capability to support same-day and complex restorations without outsourcing.

This article examines typical material ranges, hardware constraints, and optimization strategies for 2026 workflows.

Common Materials and Typical Compatibility

Dental mills process materials grouped by hardness, heat sensitivity, and required cooling:

-

Soft/Non-Abrasive (Dry-Friendly) — PMMA (acrylics), wax, PEEK/PEKK, composites, hybrid resins. These mill quickly with minimal wear; dry processing dominates for efficiency.

-

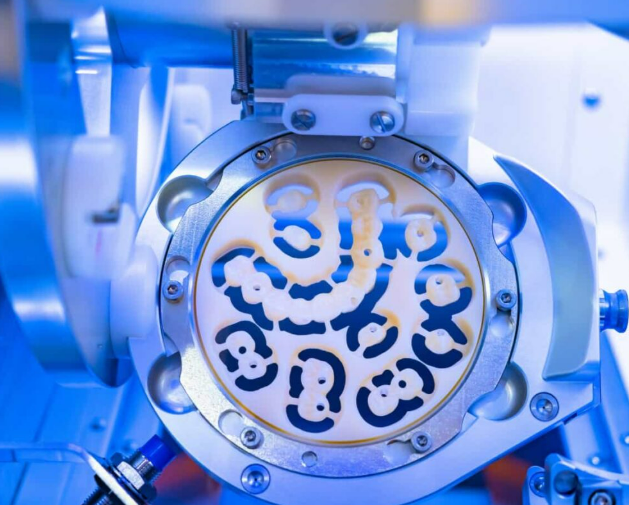

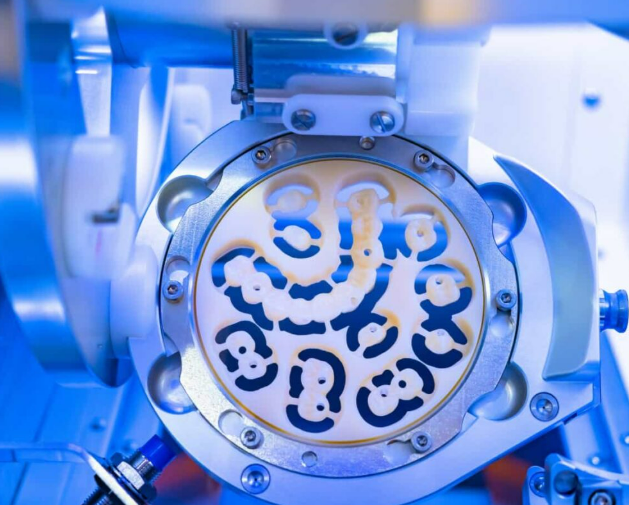

Hard Ceramics (Dry or Hybrid) — Pre-sintered zirconia (most common, ~1200 HV hardness post-sinter). Dry milling excels here, achieving 15–25 min crowns with high-speed spindles.

-

Brittle/Heat-Sensitive (Wet-Required) — Lithium disilicate (e.max-style), glass ceramics, feldspathic porcelains. Wet milling prevents microcracks and overheating; essential for esthetic anterior work.

-

Metals (Wet or Specialized) — Titanium (abutments), pre-sintered CoCr/non-precious alloys. Require wet cooling and robust spindles for precision and tool life.

Real-World Ranges (2025–2026 Data):

-

Entry/mid-range dry mills: 4–6 materials (zirconia, PMMA, wax, PEEK, composites).

-

Advanced dry/hybrid 5-axis: 7–10+ materials (zirconia, PMMA, wax, PEEK, composites, hybrid ceramics, some CoCr sintered).

-

Wet/hybrid high-end: 8–12+ materials (add lithium disilicate, glass ceramics, titanium, full metal compatibility).

Hybrid machines (switchable wet/dry) offer the broadest range, processing both zirconia (dry) and lithium disilicate (wet) without major compromises, though switching requires thorough cleaning to avoid contamination.

Primary Hardware Limitations Determining Material Compatibility

-

Cooling System (Wet vs Dry vs Hybrid) – The Biggest Restrictor

-

Dry milling suits zirconia/PMMA/wax/PEEK (fast, low-maintenance, dust via vacuum).

-

Wet milling essential for lithium disilicate/glass ceramics/titanium (coolant dissipates 200°C+ heat, prevents fractures, smoother Ra <0.2–0.4 µm finishes).

-

Pure dry machines limit to 5–7 soft/hard non-brittle materials; attempting wet-required ones risks chipping, poor fit, or tool failure.

-

Hybrids expand to 10+ materials but add maintenance (coolant changes bi-weekly, filter cleaning) and potential cross-contamination risks if not cleaned properly.

-

Data shows wet achieves 10–15% better hardness/stability in zirconia, but dry leads in speed (16 min vs 28 min for certain ceramics).

-

Spindle Speed, Power, and Bearings

-

Spindle RPM (50,000–100,000+) and power (0.5–1.8 kW) dictate hard-material handling.

-

Zirconia/titanium need high torque/low vibration for efficient cutting without excessive force.

-

Lower-spec spindles (e.g., <60,000 RPM) struggle with metals or dense ceramics, limiting to soft materials only.

-

High-frequency spindles with ceramic bearings extend tool life 20–50% across materials.

-

Number of Axes (4 vs 5)

-

4-axis: Sufficient for basic crowns/bridges (up to 3–4 units); limits undercuts/angulated abutments.

-

5-axis: Enables complex geometries (full-arch, bars, custom abutments); supports more indications across materials without repositioning.

-

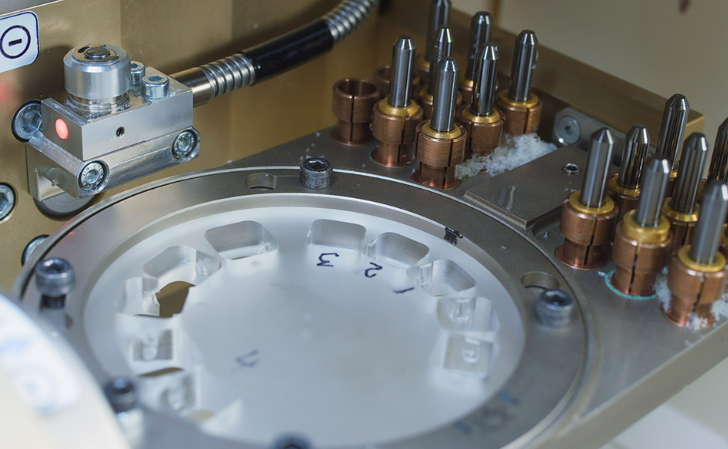

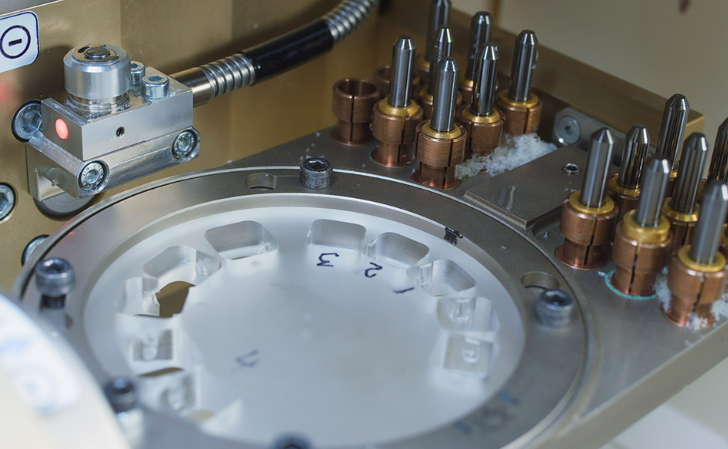

Tool Changer and Strategy

-

Auto-changers (10–30 positions) allow material-specific burs (diamond for ceramics, carbide for metals), expanding compatibility.

-

Optimized CAM paths reduce wear; poor strategy limits hard materials.

-

Machine Rigidity, Vibration Control, and Size

-

Rigid frames (cast aluminum/composite) maintain ±5–10 µm accuracy during long runs.

-

High vibration (>0.01 mm) degrades fit on brittle materials.

Optimization Strategies for Maximum Material Versatility

-

Choose Hybrid for Growth — Labs handling 30%+ esthetics/implants benefit most; supports zirconia (dry), lithium disilicate (wet), titanium.

-

Material-Specific Parameters — Use manufacturer guidelines: high RPM/low feed for zirconia; moderate RPM/high coolant for glass ceramics.

-

Maintenance Impact — Regular calibration, tool changes, and cooling system care extend compatibility and lifespan.

-

Future-Proofing in 2026 — With implant growth (U.S. market expanding) and multilayer zirconia/hybrid ceramics rising, hybrids offer best ROI via reduced outsourcing.

Conclusion: Hardware Dictates Versatility – Align with Your Workflow

A single dental CAD/CAM milling machine can process 5–12+ materials depending on design. Dry-focused machines excel for zirconia-dominant labs (high volume, speed), while wet/hybrids unlock broadest compatibility for esthetic, implant, and metal work. Key hardware limits—cooling type, spindle capability, and axes—determine true multi-material potential.

For Los Angeles practices scaling digital dentistry amid cosmetic/implant demand, evaluate your case mix: prioritize hybrid 5-axis systems for future-proof versatility, superior fit (<50–120 µm margins), and efficiency. The right machine doesn't just mill—it expands clinical offerings and boosts practice profitability.