Benefits of Zirconium Dioxide All-Ceramic Teeth

2024-10-16

2026-01-14

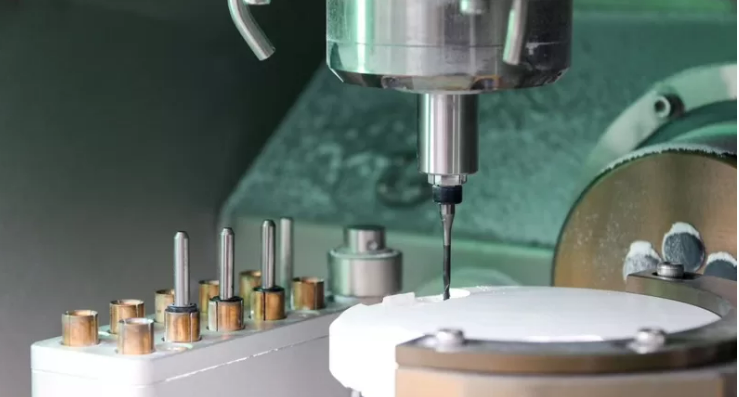

In dental CAD/CAM workflows, the milling process generates significant frictional heat—often exceeding 200°C during cutting of hard materials like zirconia or glass ceramics. This heat affects tool wear, spindle temperature, material integrity, and final restoration quality. Cooling systems address this through two primary methods: dry milling (using air/vacuum for debris removal) and wet milling (circulating water or coolant to dissipate heat).

Dry milling dominates for pre-sintered zirconia, PMMA, and wax due to speed and simplicity, while wet milling is essential for brittle materials like lithium disilicate and titanium. Hybrid machines offer both, but the choice impacts machine longevity, tool lifespan, surface finish, marginal fit, and clinical outcomes. With the global dental CAD/CAM market projected to reach $3.1–7.48 billion by 2034 (CAGR ~10%), understanding these differences helps labs and clinics—especially in high-demand areas like Los Angeles—optimize investments for precision and durability.

Dry milling relies on high-velocity air (7–80 L/min) and powerful vacuum extraction to remove zirconia dust without liquid. It avoids coolant management but can lead to higher localized heat if spindle speeds and feed rates are aggressive.

Wet milling uses a continuous flow of water or oil/glycol-based coolant (5–10 L/hour) to lubricate, cool, and flush debris. This suppresses friction and prevents thermal damage, though it requires filtration, pump maintenance, and post-milling drying for some materials.

Both approaches support high-speed spindles (50,000–100,000 RPM), but cooling strategy determines performance across materials.

Heat and vibration are primary threats to milling machine longevity, particularly the spindle—the "heart" of the system.

Studies show wet-milled zirconia specimens exhibit superior mechanical properties (higher biaxial flexural strength) at various sintering temperatures, partly due to less heat-induced phase transformation during processing.

Restoration success depends on surface roughness (Ra), marginal fit (<120 µm clinically acceptable), and absence of microcracks.

Clinical studies confirm that smoother, cooler-milled surfaces reduce plaque accumulation and enhance biocompatibility.

Wet Milling Advantages:

Wet Milling Disadvantages:

Dry Milling Advantages:

Dry Milling Disadvantages:

Hybrid systems balance both but require thorough cleaning when switching to avoid cross-contamination.

In competitive markets like California, where same-day and aesthetic demands rise, selecting the right cooling approach boosts throughput, reduces remakes (15–25% potential drop), and improves patient outcomes.

Neither wet nor dry is universally superior; the best cooling system aligns with your primary materials and case mix. Wet milling excels for machine/component protection, tool longevity, and premium restoration quality in heat-sensitive applications. Dry milling wins for speed, simplicity, and zirconia efficiency.

For most modern U.S. labs scaling in 2026, a hybrid or dual-setup strategy maximizes versatility amid growing implant and all-ceramic trends. Prioritizing proper cooling—wet or dry—ensures durable machines and clinically excellent restorations that enhance practice success.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more