What is a dental milling machine ?

2024-09-23

2026-01-20

In the vast expanse of Oceania, where innovation meets the demands of modern healthcare, the dental industry is undergoing a profound digital transformation. At the heart of this shift is Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) technology, which is redefining how dental restorations are designed, produced, and delivered. Australia and New Zealand, as leading nations in this region, are spearheading the adoption of these digital tools, driven by a commitment to precision, efficiency, and enhanced patient care. This evolution not only streamlines clinical workflows but also positions Oceania as a hub for advanced dental practices in the Asia-Pacific area.

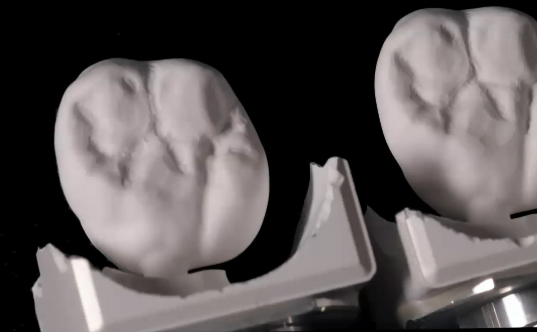

CAD/CAM systems integrate digital scanning, design software, and manufacturing processes to create custom dental prosthetics such as crowns, bridges, veneers, and implants. Unlike traditional methods that rely on manual impressions and labor-intensive lab work, CAD/CAM enables same-day restorations in many cases, reducing patient visits and minimizing errors. In Australia and New Zealand, this technology is increasingly integrated into both clinical and laboratory settings, fostering a seamless digital ecosystem that benefits practitioners, technicians, and patients alike.

Australia's digital dentistry market exemplifies the rapid growth fueled by CAD/CAM advancements. Valued at nearly $72 million in 2023, the sector is projected to expand at a compound annual growth rate (CAGR) of 5.3%, reaching over $103 million by 2030. This growth encompasses CAD/CAM devices, materials, dental 3D printers, and related software, reflecting a broader trend toward digitization in restorative dentistry.

Key drivers include technological enhancements that improve accuracy and speed. For instance, intraoral scanners capture precise 3D images of patients' teeth, eliminating the discomfort of traditional molds. These digital impressions are then used in CAD software to design restorations, which are milled or 3D-printed on-site or in specialized labs. Australian dental laboratories have embraced this shift, reporting reduced production times and improved fit for prosthetics, which translates to fewer adjustments and higher patient satisfaction.

Government initiatives and professional bodies in Australia support this transition. The Australian Dental Association promotes digital education, ensuring practitioners stay abreast of innovations. Moreover, the integration of CAD/CAM with other digital tools like cone-beam computed tomography (CBCT) enhances diagnostic capabilities, allowing for more predictable outcomes in complex procedures such as implant placements.

In urban centers like Sydney and Melbourne, clinics are adopting chairside CAD/CAM systems, enabling single-visit treatments. This not only optimizes workflow but also caters to the busy lifestyles of Australian patients. Rural areas benefit too, as digital files can be shared remotely with central labs, bridging geographical gaps and improving access to quality care.

New Zealand's dental sector mirrors Australia's momentum but with a unique focus on data standardization and national integration. Te Whatu Ora Health New Zealand is leading efforts to unify oral health data across public systems, addressing fragmentation caused by disparate applications. This initiative paves the way for better interoperability, where CAD/CAM data can seamlessly integrate with electronic health records, fostering a learning health system.

The Institute of Digital Dentistry in New Zealand serves as a pioneering training center dedicated to CAD/CAM and digital workflows. It offers specialized courses for clinicians and technicians, emphasizing practical skills in scanning, design, and manufacturing. This educational push ensures that New Zealand's dental workforce is equipped for the digital age, with graduates proficient in using AI-assisted tools for enhanced diagnostics and treatment planning.

Market-wise, New Zealand contributes to the broader ANZ (Australia and New Zealand) CAD software landscape, projected to grow from $80.6 million in 2025 to $153.0 million by 2032 at a CAGR of 9.6%. This expansion is bolstered by government support for digital technologies, including incentives for adopting building information modeling (BIM) analogs in dentistry. In regions like Auckland and Wellington, digital labs are proliferating, offering services in 3D printing for dentures and orthodontics, which reduce material waste and production costs.

New Zealand's emphasis on sustainability aligns with CAD/CAM's eco-friendly aspects, such as minimized physical waste from traditional casting. Clinics here are increasingly using biocompatible materials compatible with digital milling, ensuring restorations are durable and aesthetically pleasing.

The adoption of CAD/CAM in Australia and New Zealand brings multifaceted advantages. Foremost is precision: Digital designs achieve sub-micron accuracy, leading to better-fitting restorations and reduced chair time. This accuracy minimizes post-insertion complications, enhancing long-term success rates for procedures like crowns and bridges.

Efficiency is another cornerstone. Traditional methods could take weeks; CAD/CAM shortens this to hours. In a single appointment, a dentist can scan, design, and fabricate a restoration, improving patient convenience and practice productivity. For laboratories, digital workflows allow for batch processing and customization at scale, catering to the growing demand for personalized dentistry.

Patient comfort is significantly elevated. Intraoral scanning is non-invasive, avoiding gag reflexes associated with impression materials. Moreover, digital previews enable patients to visualize outcomes, fostering informed consent and satisfaction.

From an economic perspective, while initial investments in CAD/CAM equipment are substantial, the return on investment is evident through reduced lab fees, fewer remakes, and increased case throughput. In Oceania, where healthcare costs are a concern, this cost-effectiveness supports accessible high-quality care.

Integration with emerging technologies amplifies these benefits. Artificial intelligence (AI) in CAD software automates design suggestions, while 3D printing expands material options for temporary and permanent restorations. In Australia, AI-driven tools are being explored for predictive analytics in restorative planning, further streamlining processes.

Preparing the next generation of dental professionals is crucial for sustaining this digital shift. In Australia, researchers have developed curriculum frameworks to equip graduates with skills in digital transformation, including electronic health records, AI, and CAD/CAM workflows. Universities incorporate hands-on training with simulators and real-world applications, ensuring new dentists are "future-ready."

New Zealand's approach is similarly proactive. The aforementioned Institute provides online and in-person training, covering everything from basic scanning to advanced implant design. Annual conferences, such as the Digital Dentistry & Dental Technology event in Sydney, attract professionals from both countries, featuring sessions on intraoral scanning, 3D printing, and CBCT integration. These gatherings facilitate knowledge exchange, driving regional collaboration.

Workforce development extends to technicians. Digital dental labs in Australia and New Zealand offer apprenticeships focused on CAD/CAM, blending artistry with technology. This upskilling addresses skill gaps, ensuring a robust supply chain for digital restorations.

Despite the progress, challenges persist. High upfront costs for CAD/CAM systems can deter smaller practices, particularly in remote Oceania areas. Interoperability issues between software platforms require standardization efforts, as seen in New Zealand's data project. Additionally, cybersecurity concerns in digital health records necessitate robust protocols.

Looking ahead, the future is promising. With market growth projections and ongoing innovations, CAD/CAM will likely incorporate more AI for automated diagnostics and personalized treatments. Tele-dentistry, enabled by digital sharing, could expand access in underserved regions. By 2030, experts anticipate widespread adoption, making digital workflows the standard in Oceania's dentistry.

In conclusion, the digital transformation via CAD/CAM in Australia and New Zealand is not just a technological upgrade but a paradigm shift toward patient-centered, efficient care. As Oceania continues to embrace these advancements, the dental landscape will evolve, setting benchmarks for global practices. This journey underscores the region's commitment to innovation, ensuring brighter smiles for generations to come.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more