What is a dental milling machine ?

2024-09-23

2025-09-12

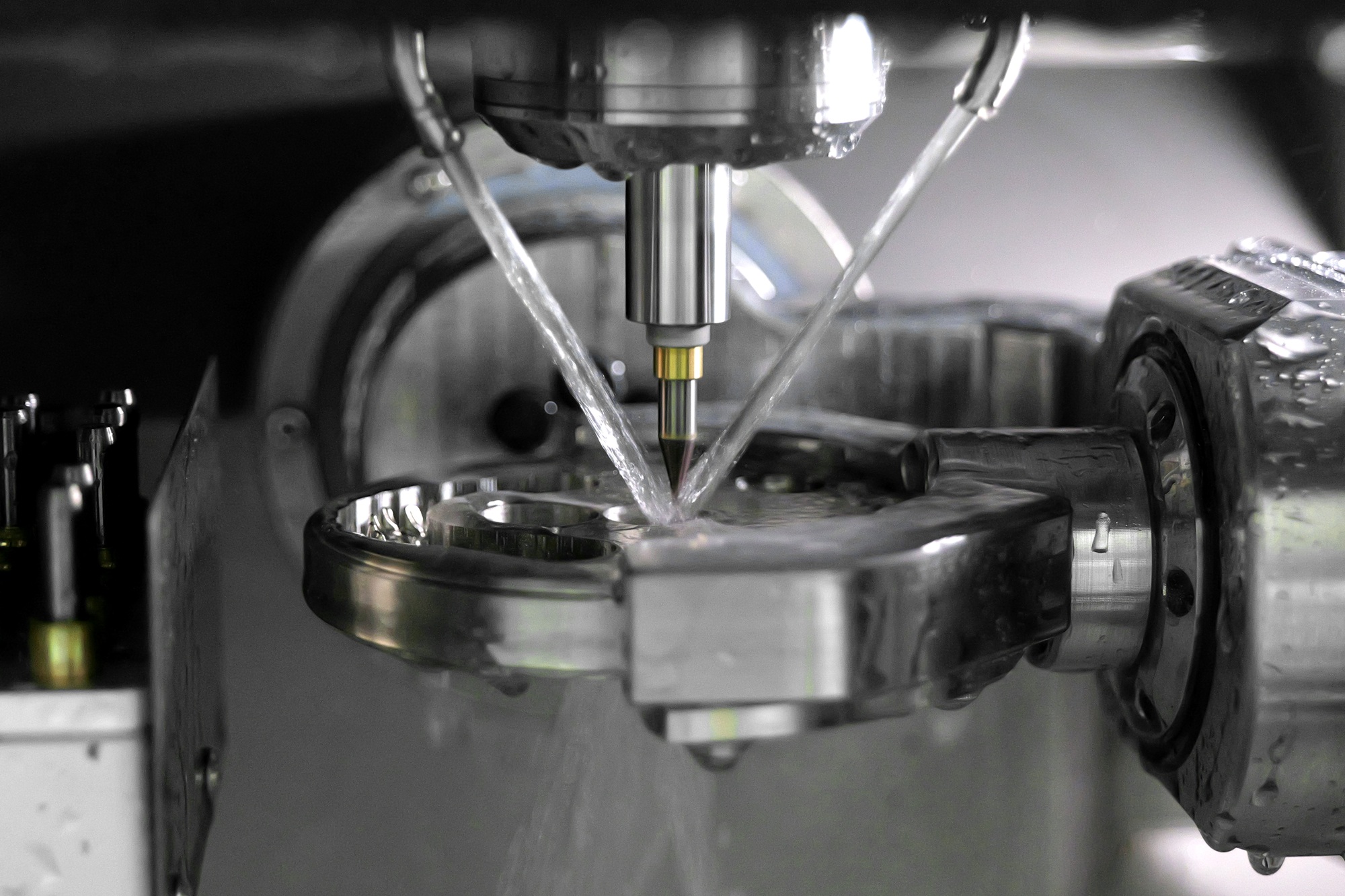

Let's break down the technical specs starting with the axes: a 3+2 simultaneous system with X-Y-Z strokes of 160mm x 115mm x 105mm, A-axis rotation of ±360°, and B-axis tilt from -30° to +90°. This setup enables complex 90° vertical milling, ensuring accurate occlusal and proximal details with ±0.05 mm precision—an industrial standard that minimizes post-milling adjustments.

The spindle is a highlight: 60,000 RPM at 2.5kW, water-cooled with Φ6 mm collets, and feed rates up to 10,000 mm/min. This power allows for efficient handling of tough materials like titanium without overheating or vibration.

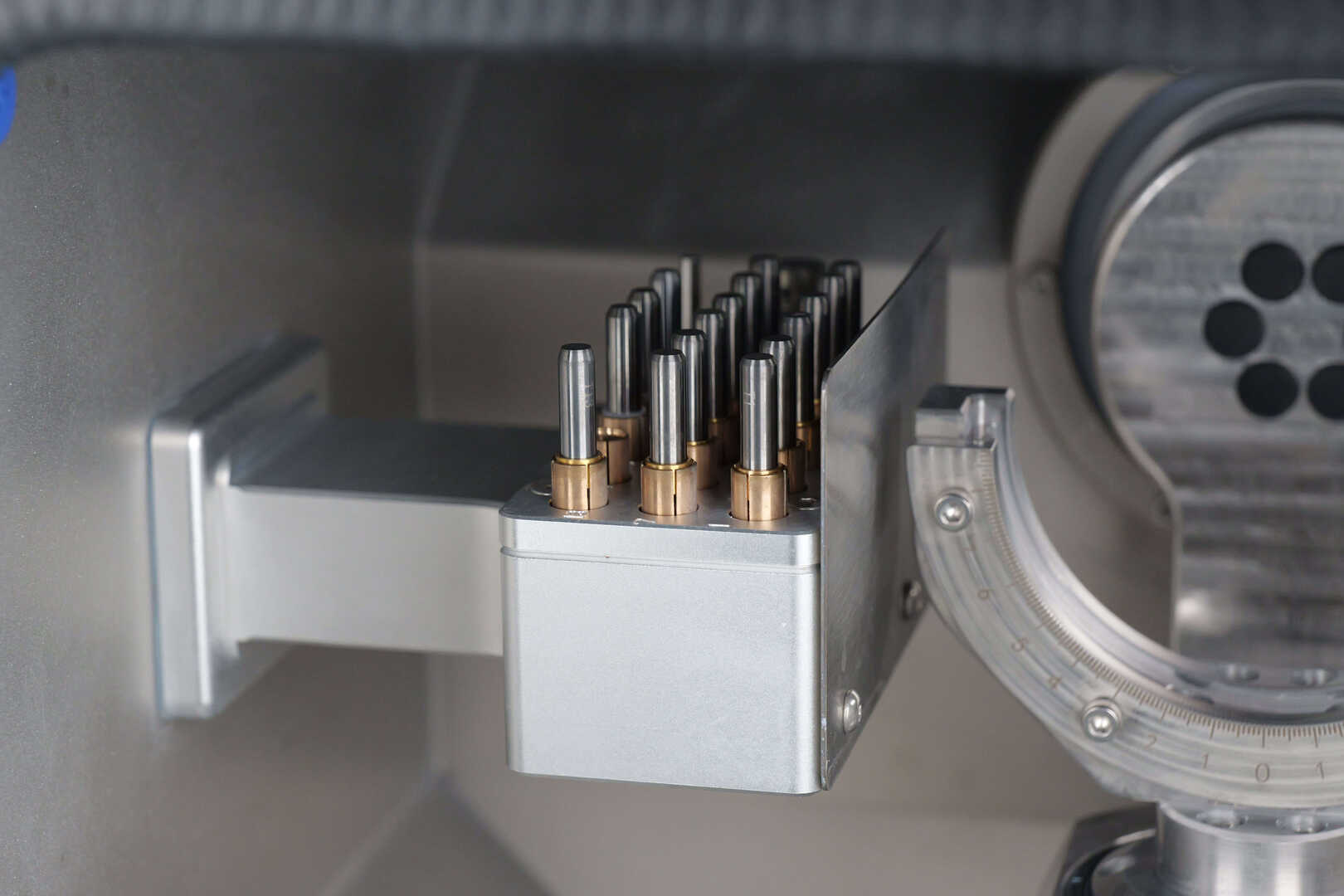

Tool management is sophisticated, with an 18-slot changer and AI-driven wear monitoring. Real-time diagnostics prevent failures, while automated calibration maintains quality across runs.

The control system uses an embedded multi-axis CNC with servo motors, powered by 220V single-phase (3.7kW total). It supports CAD/CAM integration for intuitive operation.

Physically, it's compact at 525x700x784mm and 150kg, with 6Bar air and 10L water needs. The hydrophobic system ensures clean wet milling, protecting components.

Benefits include versatility for 10-25mm materials and remote monitoring for data-driven management.

In comparison to legacy systems, the YRC-8PRO's automation reduces errors by up to 40%, per industry benchmarks.

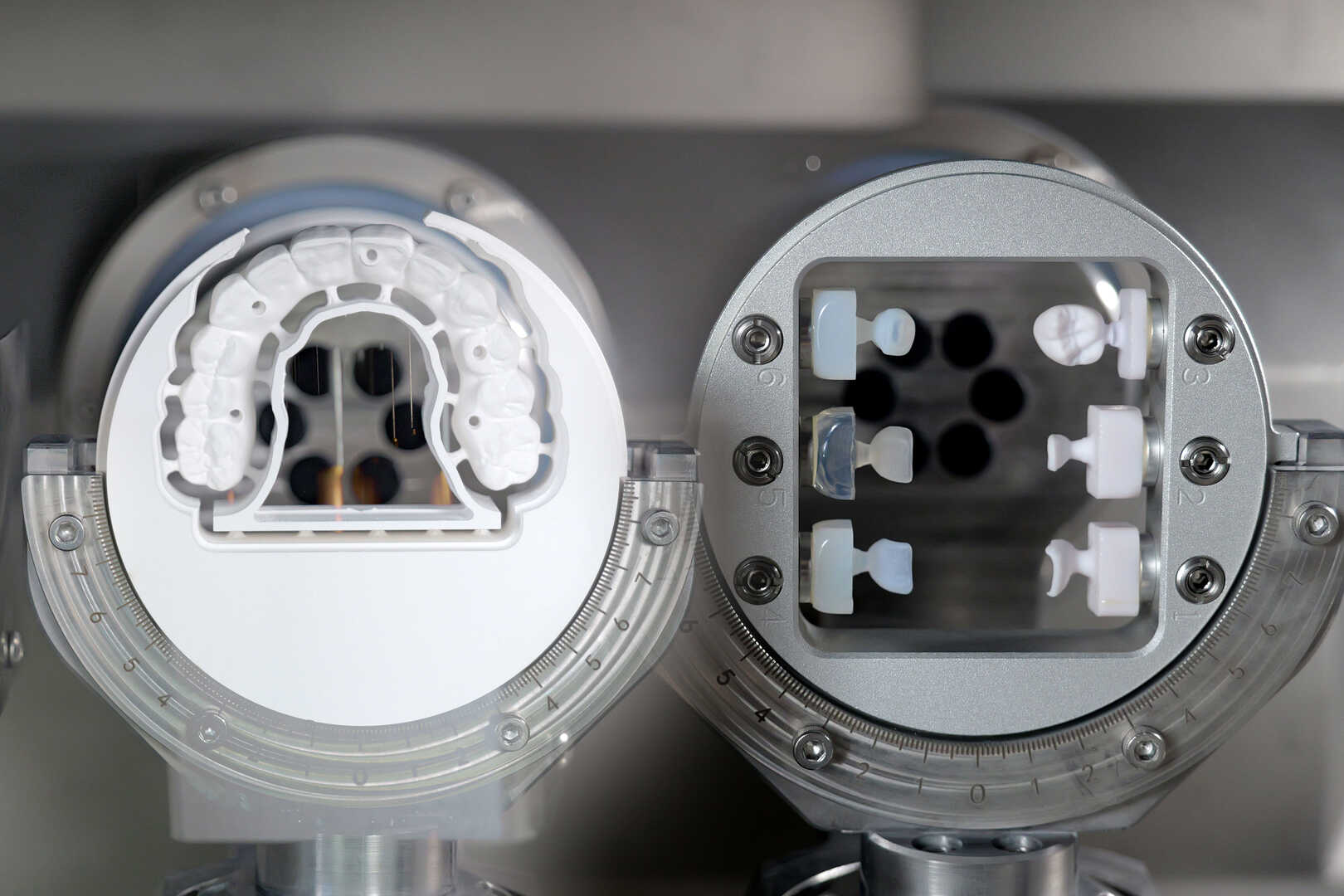

Fixtures like C-CLAMP and premill holders enhance stability.

For in-depth specs, explore the YRC-8PRO page here.

The YRC-8PRO exemplifies technical excellence, pushing dental milling boundaries.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more