Dental CAD/CAM Full Process Explained: From Scanning to Restoration – Master Digital Dentistry

2025-12-24

2026-01-13

As digital dentistry advances rapidly, the choice between 4-axis and 5-axis CAD/CAM milling machines remains pivotal for dental labs and clinics. By 2026, rising demand for same-day restorations, complex implant-supported prosthetics, and high-strength materials like zirconia, glass ceramics, and titanium drives the decision. 4-axis mills offer affordability and simplicity for standard work, while 5-axis systems provide superior versatility and precision for advanced cases.

The U.S. dental implants market is projected to grow from approximately USD 1.4–1.66 billion in 2025 to USD 2.3–3.2 billion by 2033–2034 (CAGR 5.8–7%+), fueled by aging populations and cosmetic demand. Overall dental milling market growth hovers around 8–9.5% CAGR, with 5-axis adoption accelerating due to broader indications. This article compares the two technologies across capabilities, performance, costs, and ROI to guide 2026 investment decisions for U.S.-based practices.

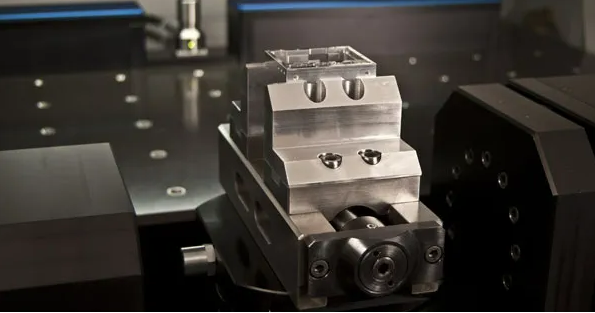

A 4-axis milling machine typically includes three linear axes (X, Y, Z) plus one rotary axis (usually A-axis for 360° rotation around X). This setup suits basic tilting and rotation for crowns, bridges, inlays, onlays, and simple multi-unit frameworks.

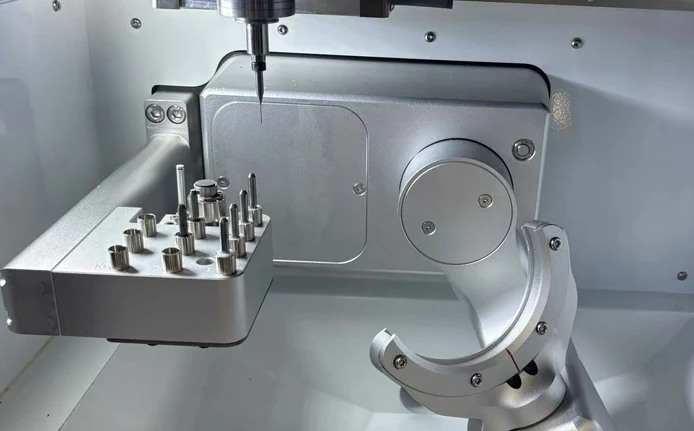

A 5-axis machine adds a second rotary axis (B-axis), enabling simultaneous movement in five directions. The workpiece tilts and rotates freely, allowing access to undercuts, angled channels, and complex geometries without repositioning or excessive supports.

This extra degree of freedom in 5-axis systems minimizes collisions, reduces manual intervention, and optimizes tool paths for full-contour and hybrid restorations.

4-axis mills excel in high-volume production of single-unit and short-span restorations:

They handle most posterior and anterior cases efficiently but struggle with severe undercuts, highly angulated implant abutments, full-arch screw-retained bridges, bars, or titanium custom components. Some designs require multiple setups or post-milling adjustments, increasing labor.

5-axis mills expand indications significantly:

5-axis technology supports simultaneous machining that reduces stair-stepping on curved surfaces and enables thinner, more aesthetic margins. In labs handling 30%+ implant-related work—a common threshold in growing U.S. markets—this versatility proves essential.

Precision defines long-term success. Marginal gaps ideally stay under 120 µm to minimize microleakage, secondary caries, and cement dissolution.

Studies consistently show 5-axis machines achieve superior marginal and internal fit compared to 4-axis. 5-axis copings exhibit smaller, more consistent gaps (often 20–50 µm better average), with reduced variation across restorations. This translates to fewer chairside adjustments, lower remake rates (potentially 15–25% reduction), and extended clinical longevity (10–15+ years for well-fitted zirconia crowns).

Surface roughness also improves with 5-axis: optimized tool engagement reduces Ra values (smoother finishes ~0.4–1.0 µm on zirconia vs. higher in 4-axis for complex shapes), enhancing polishability, plaque resistance, and aesthetics.

Vibration control and rigid construction in premium 5-axis spindles (often 60,000–100,000 RPM) maintain micron-level accuracy (±10–25 µm positioning) throughout runs.

5-axis machines often mill 40–60% faster for comparable or complex cases due to continuous tool engagement and fewer interruptions. Example: A glass-ceramic crown might take ~40 minutes on 4-axis vs. ~25 minutes on 5-axis; full-contour zirconia single crowns complete in 15–25 minutes on optimized 5-axis systems.

Daily output benefits high-volume labs: 5-axis with auto-tool changers and larger material capacities support 100–200+ units/day vs. 60–120 for 4-axis equivalents. Reduced manual finishing and remakes add 20–40% overall efficiency gains.

Energy use and tool wear improve with proper 5-axis paths, extending tool life by 20–50% in balanced operations.

Initial investment (2025–2026 estimates for mid-range dry/wet-capable models):

5-axis commands 50–100%+ premium due to mechanics, software, and controls.

Ongoing costs: 4-axis lower maintenance and simpler operation/training. 5-axis higher initial training (1–2 weeks) but offset by versatility; annual maintenance ~5–8% of purchase price for both.

Software: Many 5-axis require advanced CAM (additional USD 5k–15k initially), though integrated solutions reduce this gap by 2026.

ROI depends on case mix and volume. A small lab focused on standard crowns (80%+ single-unit) may achieve payback on a 4-axis in 12–18 months via low cost and reliability.

Medium-to-large labs or implant-focused practices (20–40%+ complex cases) favor 5-axis: broader indications capture higher-fee jobs (implant bars/abutments), reduce outsourcing, and boost throughput. Reported payback periods: 12–24 months in active U.S. labs, driven by 20–40% efficiency gains, lower remake rates, and material savings (better nesting/less waste).

In high-demand U.S. markets (e.g., California, Florida, Texas with strong cosmetic/implant growth), 5-axis supports premium same-day or next-day services, increasing patient volume and revenue per chair/hour.

By 2026, dental CAD/CAM milling grows steadily (overall market USD 2.3–3+ billion range with 8–10% CAGR), with 5-axis comprising a rising share due to:

4-axis remains viable for entry-level or backup mills, but future-proofing favors 5-axis for scalability.

4-Axis Pros: Lower cost, easier learning curve, sufficient for 70–80% standard cases, compact footprint, faster setup for simple jobs. 4-Axis Cons: Limited indications, potential multiple setups, more manual finishing for complex work, higher remake risk on undercuts.

5-Axis Pros: Unlimited geometries, superior precision/fit, faster complex milling, broader material compatibility, higher revenue potential. 5-Axis Cons: Higher upfront cost, steeper learning curve, larger space/complexity, overkill for very basic labs.

For small clinics or labs with predominantly single-unit and simple bridge work (<20% implants/complex), a 4-axis machine offers excellent value—affordable entry into digital workflows with quick ROI.

For most modern U.S. labs, clinics scaling to implants, full-arch, or high-volume production, 5-axis is the smarter long-term investment in 2026. Versatility future-proofs operations amid rising implant demand and complex case prevalence. Efficiency gains and premium service capabilities typically yield faster overall returns despite higher initial outlay.

Hybrid approach (primary 5-axis + secondary 4-axis for overflow) maximizes flexibility in larger setups. Evaluate your annual case volume, % of implant/abutment work, and growth projections before deciding.

The 4-axis vs 5-axis choice hinges on your practice's current needs and future ambitions. While 4-axis delivers reliable performance at lower cost, 5-axis technology's precision, speed, and expanded capabilities align better with 2026 trends toward comprehensive digital dentistry and implant-driven growth. Investing in the right mill elevates restoration quality, operational efficiency, and patient outcomes—ultimately strengthening competitiveness in a booming U.S. dental market.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more